Technology Overview

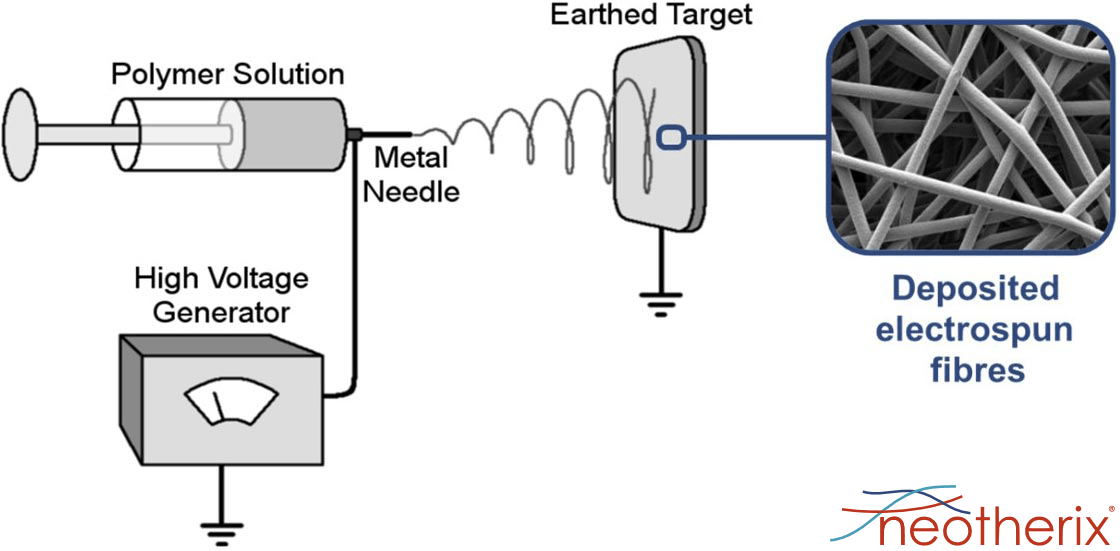

Neotherix uses the polymer processing technique of electrospinning to manufacture scaffolds. This involves the application of a high voltage electric field to a polymer solution under controlled conditions, so that mutual charge repulsion on the surface of the liquid overcomes the surface tension and causes a thin liquid jet to be ejected. As the jet travels towards a collector a combination of electric charge effects causes a large reduction in the diameter of the jet and very fine, attenuated polymer fibres between 10nm to 10µm are formed and deposited.

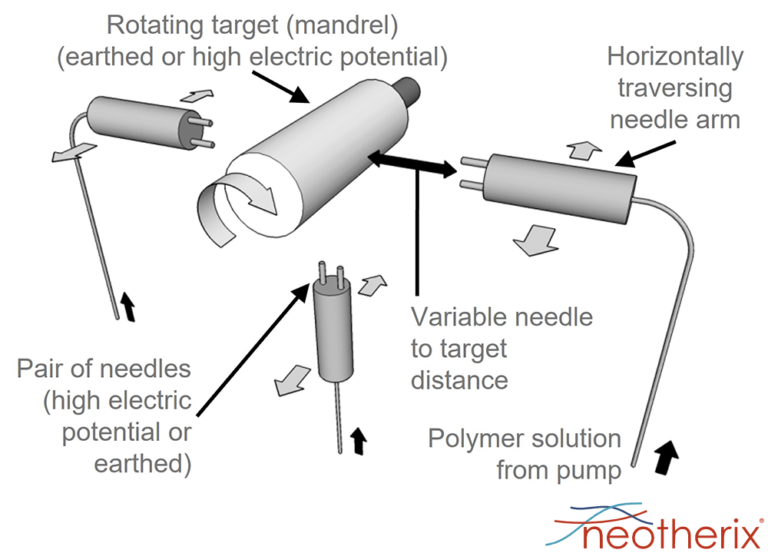

Bespoke electrospinning set-up options

Neotherix have succeeded in controlling the large number of electrospinning conditions that can influence the output (e.g. temperature, humidity, optimal solvent, surface tension at the point of electrospinning) to produce uniform bioresorbable scaffolds. A bespoke electrospinning rig allows reliable prototype, pilot or scaled-up production campaigns to be run.